The Power of Talc Powder: 5 Refractory Uses

Discover the Refractory Benefits of Dolomite Powder

February 22, 2023

The Many Benefits Of Ground Calcium Carbonate From Mewar..

March 27, 2023

Introduction:

Talc powder is one of the oldest known minerals, and it is becoming increasingly popular for its 5 refractory uses. From being used as a lubricant for crafting molds to providing heat resistance for steel structures, talc is a multi-purpose mineral that has many benefits to offer. This article will discuss the different refractory uses of talc powder, their advantages, and how their adoption could potentially lead to better overall results.

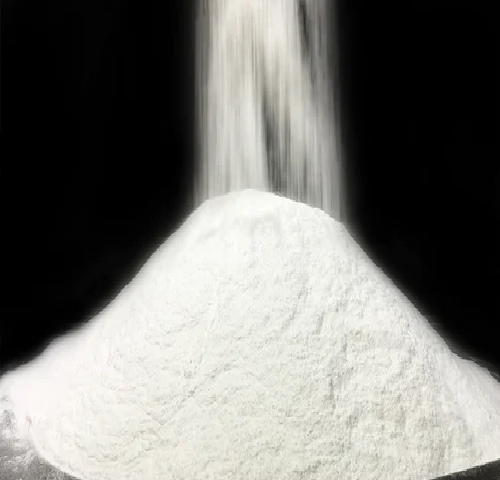

What Is Talc Powder?

Talc is a type of mineral that can be found in nature as masses of rock-like structures. Talc powder refers to a white and soft powder form of the mineral that's extensively used for multiple industries. It has a high lubricity and helps improve the flow, reduce viscosity and hydration properties when added to finely-ground materials.

Refractory Uses of Talc Powder

A. Molding and Casting

Talc powder is commonly used in the molding and casting process of heavy metal and light metal components. It is used as a lubricant and a parting medium to seal and fill small defects in a mold. Talc improves the mold flow characteristics, reduces sticking, sticking aid, better filling and die cast. Moreover, it also aids in reducing porosity and provides an excellent tool release capability.

B. Refractory Mortar

Refractory mortar is used to bind and seal refractory materials and other components in areas of high temperatures. By adding talc powder to the refractory mortar, it increases adhesion, impermeability, and volume stability. This improves the resistance towards rapid temperature changes, thermal fatigue, and water absorption.

C. Heat Shielding

Talc powder can be added to materials for insulation against heat radiation. Talc improves the ability to reflect heat away from metallic objects and surfaces, and is also used to treat surfaces such as glass to increase the insulation value. Furthermore, talc powder can also be used to provide a reflective barrier to protect composite laminates and other materials from heat.

D. Thermal Insulation

Talc powder is used in thermal insulation applications due to its lightweight and moisture control properties. It has the ability to reduce the conduction of thermal energy, improve its tensile rigidity, and reduce the heat transfer. It is also used in composite laminates as a protective layer to insulate against heat, fire, and extreme temperatures.

E. Refractory Coatings

Refractory coatings are used to protect surfaces from extreme temperatures, abrasions or corrosive damage. Talc powder helps improve the adhesion of the coating, extends the life of the coating, and improves its thermal insulation performance. Furthermore, talc is also used as a filler for other materials to improve its durability and ensure a smoother finish.

III. Advantages of Talc Powder

The use of talc powder for its five refractory uses has numerous advantages, including cost-effectiveness, improved thermal insulation, better adhesion, corrosion protection, and environmental sustainability. Additionally, talc powder is a versatile mineral that can be combined with other materials to improve their performance and reduce the risk of production defects. Mewar Microns is the top Supplier of Talc Powder, get yours today.

Conclusion:

Talc powder is an increasingly popular mineral that has many advantageous refractory uses, ranging from making molds to providing heat shielding and thermal insulation. The use of talc powder can provide cost-effectiveness, improved thermal insulation, better adhesion, corrosion protection, and environmental sustainability. Adopting these refractory uses could prove beneficial not only to businesses, but also to the environment.