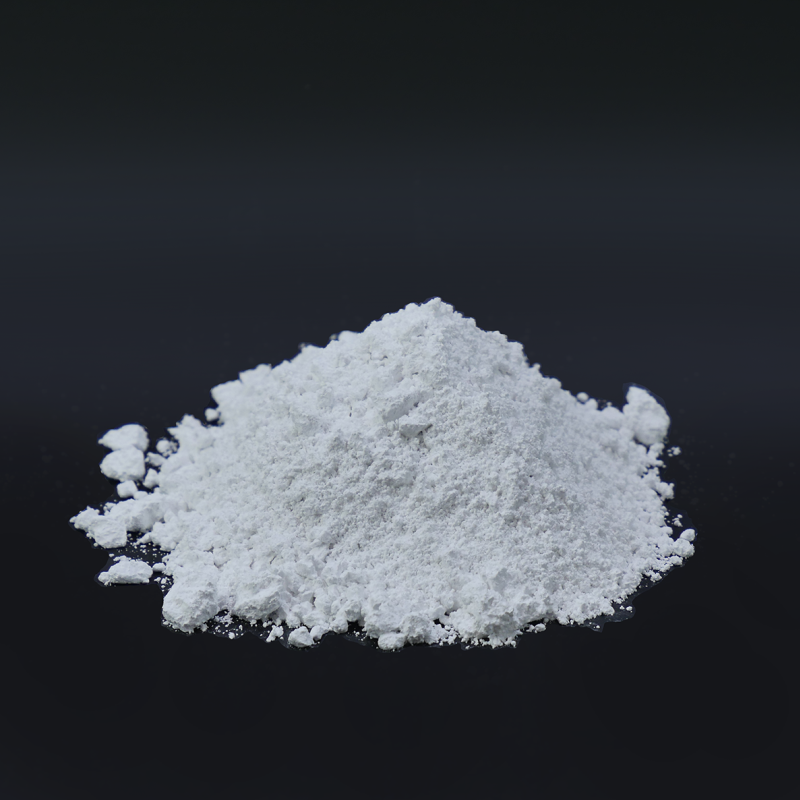

ACC- Activated calcium Carbonate Manufacturers

Activated calcium carbonate (ACC) is a versatile and highly beneficial compound that finds wide-ranging applications across various industries. As prominent Activated calcium Carbonate Manufacturers and exporter, we take pride in offering a product that is known for its exceptional quality and performance. In this page, we will discover the key features of our activated calcium carbonate, explore its diverse applications, and highlight the numerous benefits it brings to your manufacturing process.

Activated Calcium Carbonate, produced through a precise and controlled process, exhibits enhanced properties compared to conventional calcium carbonate. Our ACC offers superior dispersion, increased surface area, and improved functionality, making it an ideal choice for industries such as plastics, rubber, paints, coatings, adhesives, and more. At Mewar Microns, we understand the unique requirements of each industry. Our dedicated team of experts collaborates with clients to develop customized ACC solutions, ensuring optimum performance and cost-efficiency.

Key Features

Activated Calcium Carbonate possesses several key features that make it a highly sought-after compound in various industries. Here, we will explore these key features in detail:

Overall, ACC possesses key features such as high purity, controlled particle size, outstanding whiteness, controlled surface area, excellent chemical stability, versatility, and environmental friendliness. These features make it an ideal choice for a wide range of applications, providing manufacturers with a reliable and effective compound to enhance their manufacturing processes.

Product Specification:

| Grade Standard | Technical Grade, Industrial Grade |

| Application | Chemical Industry, Construction Industry |

| Purity % | 95.5% |

| Precipitation State | Precipitated |

| Packaging Size | Customize |

| Packing Type | Bag |

Applications

Benefits of Using Our ACC in Manufacturing Processes

Conclusion

Activated calcium carbonate, with its exceptional features, wide-ranging applications, and significant benefits, proves to be an indispensable component in numerous manufacturing processes. As Activated calcium Carbonate Manufacturers and exporters, we are committed to delivering a high-quality product that consistently meets the evolving needs of various industries. By harnessing the power of this mineral, manufacturers can enhance their product performance, improve cost-efficiency, and contribute to environmental sustainability. Choose our activated calcium carbonate and unlock new possibilities for your manufacturing processes.