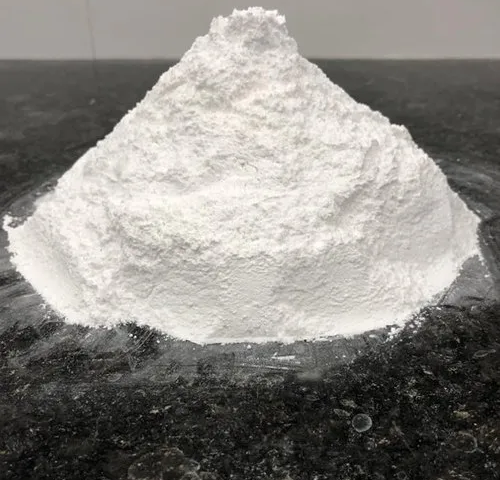

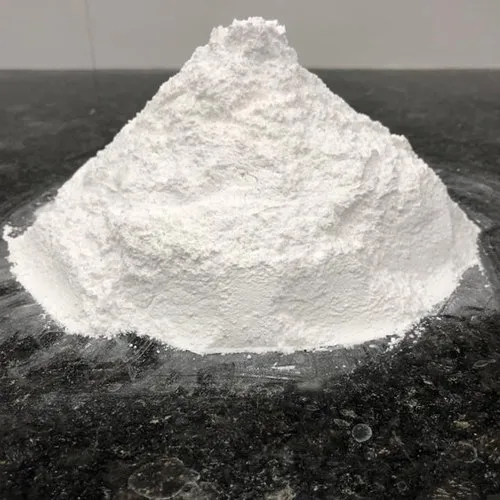

The Benefits of Using Talc Powder in Refractory Applications

4 Helpful Uses for Ground Calcium Carbonate

January 19, 2023

The Refractory Benefits of Activated Calcium Carbonate

January 21, 2023

Introduction:

Talc powder has become increasingly popular for use in refractory applications due to its numerous advantages. Talc powder is an effective addition to refractory mixes, and offers a range of benefits from improved performance to cost savings. This article examines the benefits of using talc powder in the refractory industry.

The use of talc powder in refractory applications has seen a steady increase in recent years. This powder is formed when magnesium silicate is deposited over long periods of time, resulting in an ultramarine powder that is essentially consistent with magnesium and silicon. Talc powder is widely used in the ceramics and construction industries due to its properties, which allow for a high degree of porosity and thermal shock resistance.

The Properties of Talc

Talc is a mineral composed of various naturally occurring substances, including magnesium and silicon, which form a layer of magnesium silicate. This layer is highly porous and weather resistant, making it ideal for refractory applications. Talc powder is also non- combustible and non-reactive to water, making it ideal for use in high temperature environments. Additionally, talc powder has a low thermal conductivity, meaning it can retain heat even when exposed to high temperatures.

Refractory Applications that Benefit from Talc

Talc powder is widely used in the refractory industry due to its advantageous properties. Its low thermal conductivity and high porosity make it ideal for use in the manufacturing of refractory bricks, which must withstand extreme temperatures and pressure. Talc is also used in the production of castables and cement, both of which are used in the construction of furnaces and other heat-resistant structures.

Benefits of Using Talc in Refractory Mixes

The addition of talc powder to refractory mixes can offer a number of benefits. Talc powder increases the strength of refractory mixes, by improving the density and adhesion of the mix. This improved performance can result in longer lifetime of the structure, more efficient energy use and cost savings. In addition, the thermal shock resistance of talc powder allows for more precise temperature control and faster heat-releases, resulting in a more efficient process.

Mewar Microns is a leading Supplier of Talc Powder and other related products. With a long-standing reputation for providing high quality and reliable products, the company has earned its place as one of the leading suppliers in the industry. Our Talc Powder is sourced from the best and most reliable sources, ensuring that it is of a high standard for every customer. The consistent quality and availability of the products are two of the key characteristics of our offerings as a supplier of Talc Powder. Our team of experts will ensure that the product meets customers’ needs and requirements. Mewar Microns also provides professional technical support and customer service to ensure customer satisfaction after each purchase. Furthermore, our team is highly experienced in the industry and well versed in both domestic and international trade regulations. We guarantee a reliable, safe, and timely delivery of our products. If you are looking for a supplier of quality Talc Powder, look no further than Mewar Microns.

Conclusions:

The use of talc powder in refractory applications offers a range of benefits, from improved performance to cost savings. The unique properties of talc powder make it ideal for use in the manufacture of refractory bricks and castables, and can result in improved durability and more efficient energy use. Taking the advantages of talc powder into consideration, it is clear that it is an essential addition to any refractory mix.