Ground Calcium Carbonate Manufacturer

Discover the Versatility and Benefits of Ground calcium carbonate

As a leading Ground Calcium Carbonate Manufacturer, we take pride in offering a high-quality product that boasts numerous applications across a wide range of industries. With its exceptional characteristics, our Ground calcium carbonate (GCC) is a versatile solution that has gained recognition for its outstanding performance and multiple benefits. Let's explore its key features, applications, and the advantages it brings to various sectors.

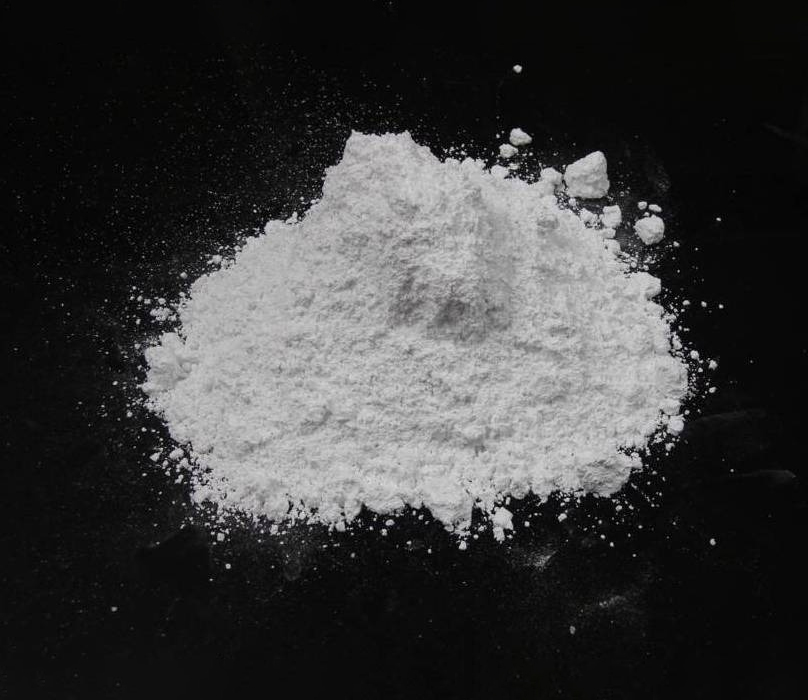

Ground Calcium Carbonate, derived from naturally occurring limestone, is processed to precise specifications to meet the demanding requirements of various industries.

Our GCC exhibits exceptional whiteness, particle size distribution, and brightness, making it suitable for applications in plastics, paints, rubber, paper, and more. At Mewar Microns, we understand the importance of consistency and reliability in delivering GCC products. Our state-of-the-art manufacturing facilities and stringent quality control ensure that our customers receive GCC of the highest standards.

Key Features

Ground Calcium Carbonate (GCC) is a versatile mineral compound that possesses several key features, making it highly sought after in various industries. Let's delve into the primary characteristics that make GCC an exceptional material for numerous applications.

In summary, our Ground calcium carbonate stands out for its purity, whiteness, fine particle size, controlled distribution, chemical composition, rheological properties, brightness, opacity, and versatility. These key features make it an indispensable ingredient in numerous manufacturing processes. GCC's exceptional characteristics contribute to improved product performance, cost efficiency, and environmental friendliness. As a reliable Ground Calcium Carbonate Manufacturer, we ensure that our product encompasses these key features, enabling our customers to unlock the full potential of this remarkable mineral compound in their respective industries.

Product Specification:

| State | Powdered |

| Packaging Size | 25Kg / 50Kg |

| Packaging Type | Packet, HDPE Bags |

| Application | Construction |

| Brand | Mewar Microns |

| Color | White |

Applications

Ground calcium carbonate (GCC) is a highly versatile mineral compound that finds extensive applications across various industries. Its unique properties make it an indispensable additive in numerous manufacturing processes. Let's explore some of the key applications of GCC:

These are just a few examples of the diverse applications of Ground calcium carbonate. Its versatility, combined with its unique properties, allows it to enhance the performance and quality of products across multiple industries. As a reliable Ground Calcium Carbonate Exporter, we are committed to providing a high-quality product that meets the specific requirements of each application, enabling our customers to achieve exceptional results.

Benefits of Using Our Ground Calcium Carbonate:

Conclusion:

With its remarkable features, diverse applications, and wide-ranging benefits, our Ground calcium carbonate stands as a premier solution for multiple industries. Whether it's enhancing the properties of plastics, paper, coatings, or adhesives, its versatility and exceptional performance make it an indispensable component in countless manufacturing processes. Partner with us and unlock the true potential of Ground calcium carbonate for your specific needs.